What is 3D Printing and Its Different Types

Share

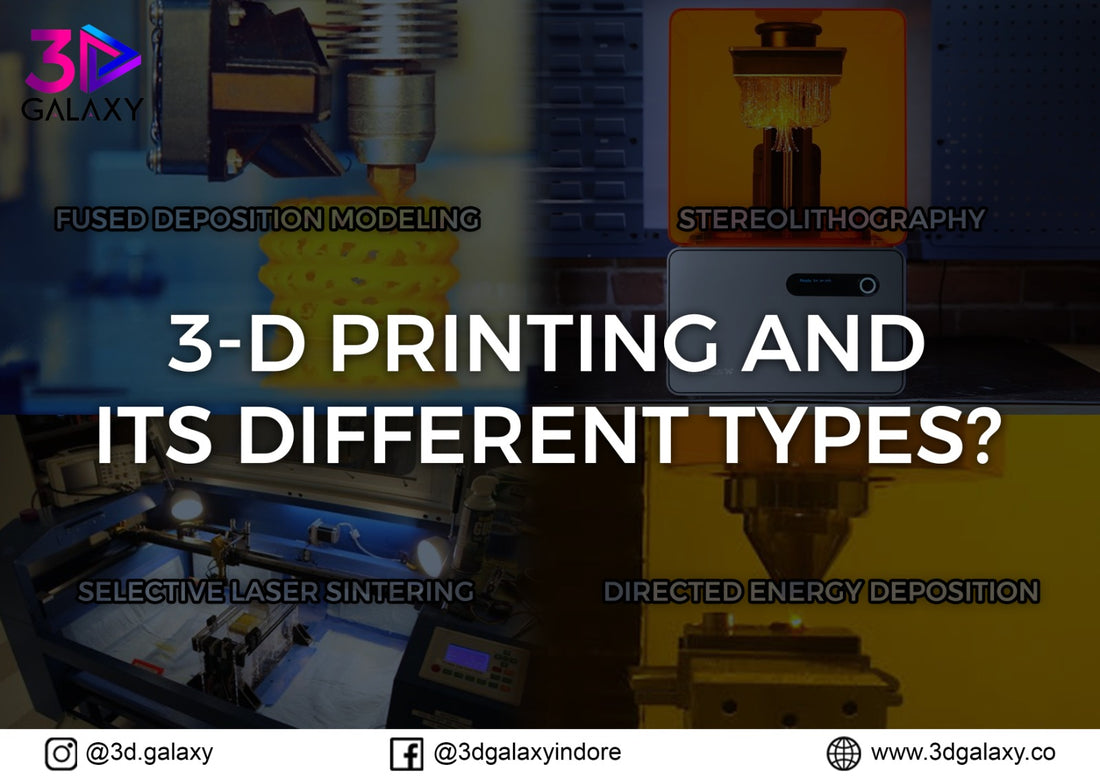

What is 3-D Printing and Its Different Types?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by building up layers of material. This technology has come a long way over the years and has evolved to encompass a wide range of techniques and materials. In this blog post, we will take a look at the most common types of 3D printing and their respective advantages and disadvantages.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is the most widely used type of 3D printing. It works by heating a filament of plastic, which is then extruded through a nozzle to create the object. The object is built up layer by layer, with each layer cooled and solidified before the next layer is added.

Advantages:

- FDM printers are relatively inexpensive and easy to use

- They can print a wide variety of materials, including ABS, PLA, and TPU

Disadvantages:

- Objects printed with FDM may not be as smooth or detailed as those printed with other methods

- The surface finish of the objects printed with FDM may not be as good as that of objects printed with other methods

Stereolithography (SLA)

Stereolithography (SLA) is another popular type of 3D printing that uses a laser to cure a liquid resin. The laser is directed at specific points on the resin, which solidifies to create the object.

Advantages:

- SLA printers are able to create highly detailed and precise objects

- The objects printed with SLA have a smooth surface finish

Disadvantages:

- SLA printers are typically more expensive than FDM printers

- The materials used in SLA printing are more expensive

- The objects printed with SLA may be more fragile and less durable than those printed with other methods

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a type of 3D printing that uses a laser to fuse together small particles of plastic, metal, or ceramic. The laser is directed at specific points on the powder, which melts and solidifies to create the object.

Advantages:

- SLS printers are able to create highly detailed and precise objects

- They are able to use a wide variety of materials, including nylon and metal

Disadvantages:

- SLS printers are typically more expensive than FDM and SLA printers

- The objects printed with SLS may be more brittle and less durable than those printed with other methods

Directed Energy Deposition (DED)

Directed Energy Deposition (DED) is a type of 3D printing that uses a heat source, such as a laser or an electron beam, to melt and deposit material in order to build up an object. It is typically used to repair or enhance existing parts, often made of metal.

Advantages:

- DED is a fast process, allowing for large parts to be built quickly

- DED can be used for a wide range of materials, including metals

Disadvantages:

- DED can be a complex process, requiring specialized equipment and expertise

- The cost of the equipment and the materials used in DED can be high

Conclusion

There are many different types of 3D printing technology available, each with its own set of advantages and disadvantages. Fused Deposition Modeling (FDM) is the most widely used, but Stereolithography (SLA) and Selective Laser Sintering (SLS) are also popular choices for more detailed and precise objects. Directed Energy Deposition (DED), binder jetting, material jetting, and digital light processing (DLP) are also types of 3D printing that are used for specific applications. Ultimately, the choice of 3D printing technology will depend on the specific needs of the project and the desired end result. It's essential to do your research and understand the pros and cons of each type of 3D printing technology before making a decision