Types of 3D Printing Materials used in FDM

Share

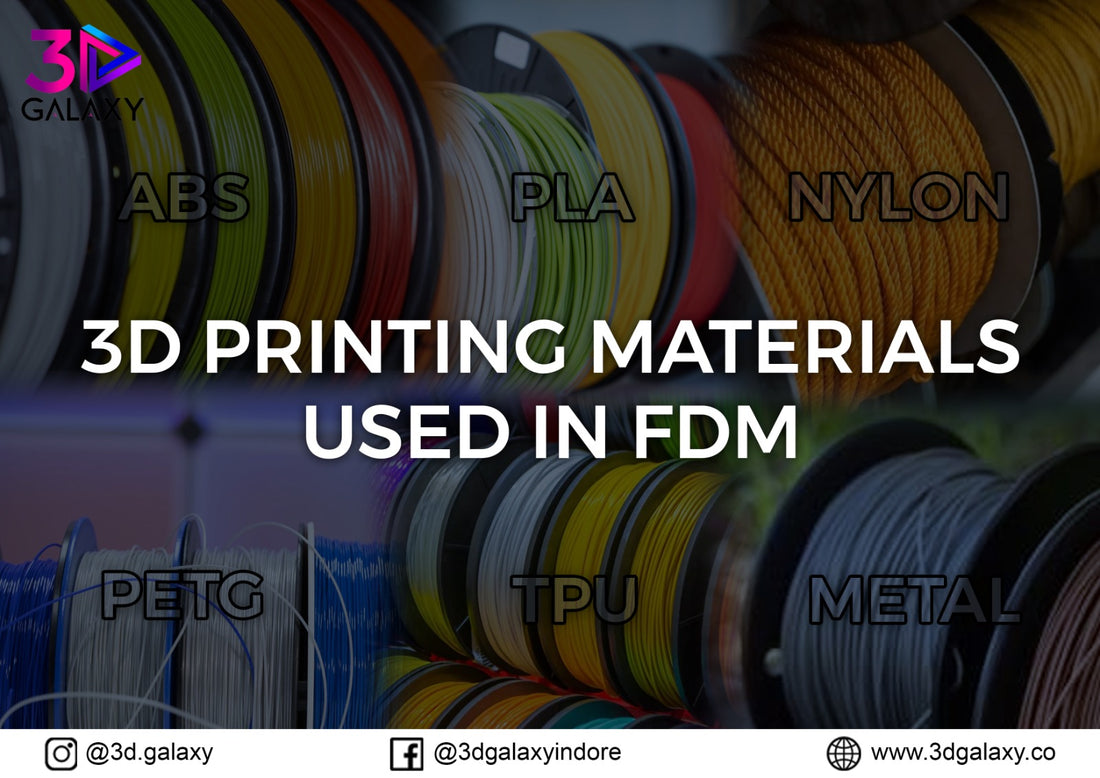

Types of 3D Printing Materials used in FDM

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by building up layers of material. One of the most popular 3D printing technologies is FDM (Fused Deposition Modeling), which uses a filament of thermoplastic material that is extruded through a heated nozzle to create the object.

There are many different types of materials that can be used in FDM 3D printing, each with their own unique properties and applications. In this blog post, we will explore some of the most commonly used materials in FDM 3D printing.

Most Commonly Used Materials In 3D Printing

ABS (Acrylonitrile Butadiene Styrene)

ABS is a thermoplastic polymer that is known for its strength, durability, and flexibility. It is commonly used in the manufacture of toys, automotive parts, and household appliances. ABS is also resistant to chemicals and high temperatures, making it a great choice for outdoor applications.

PLA (Polylactic Acid)

PLA is a biodegradable thermoplastic made from renewable resources such as corn starch or sugarcane. It is known for its low environmental impact and is commonly used in the food industry, such as in packaging materials. PLA is also easy to print with, and produces less odor during the printing process.

PETG (Polyethylene Terephthalate Glycol)

PETG is a thermoplastic polymer known for its transparency, high strength, and high chemical resistance. It is commonly used in the packaging industry, such as in water bottles, and has found application in FDM 3D printing as a transparent filament.

TPU (Thermoplastic Polyurethane)

TPU is a flexible thermoplastic polymer that is known for its high resistance to oil and chemicals, as well as its good abrasion resistance. TPU is commonly used in the manufacture of flexible parts, such as phone cases and shoe soles.

Nylon

Nylon is a strong and durable thermoplastic polymer that is resistant to wear and tear. It is commonly used in the manufacture of gears, bearings, and other mechanical parts. Nylon is also known for its high resistance to chemicals and high temperatures.

Metal

Metal FDM 3D printing is a newer technology that uses metal powders, wires or sheets as the raw material for the printing process. Metal filaments are used to create prototypes or end-use parts in aerospace, automotive, and medical industries.

These are just a few of the many materials that can be used in FDM 3D printing. Each material has its own unique properties and applications, so it is important to choose the right material for your specific project. In addition to the materials listed above, there are also many other specialized filaments available, such as conductive filament, carbon fiber-reinforced filament and more.

Conclusion

In conclusion, FDM 3D printing technology has come a long way in recent years, with a wide variety of materials available to suit different applications. From ABS to metal, each material has its own unique properties and applications, making it easier for designers and engineers to choose the perfect material for their specific project.